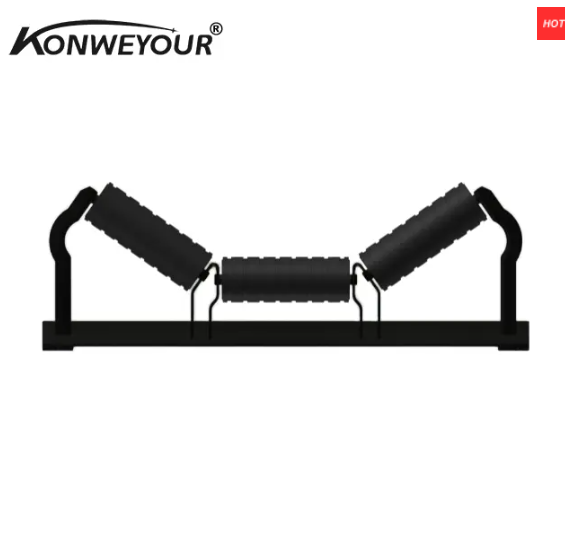

Stainless Steel Spiral Cage PulleyThe Stainless Steel Spiral Cage Pulley is engineered for demanding conveyor systems where material buildup, belt slippage, and harsh environmental conditions are common challenges. Featuring a unique spiral cage design, this pulley effectively removes debris and prevents material accumulation by allowing loose particles to fall through its open structure during rotation.Manufactured from high-grade stainless steel, it provides exceptional corrosion resistance, making it ideal for wet, abrasive, or chemically aggressive environments. The spiral configuration enhances belt contact, improving traction and reducing slippage for stable conveyor performance.With its robust structure and precision engineering, the Spiral Cage Pulley ensures reliable operation under heavy loads and contributes to lower maintenance requirements. It is widely used in industries such as mining, quarrying, cement plants, and bulk material handling, where efficiency and durability are critical.Key Features:Spiral cage design for self-cleaning and debris discharge.Stainless steel construction for superior corrosion and wear resistance.Improved belt traction and reduced slippage.Heavy-duty design for high-load capacity and long service life.Ideal for challenging industrial and environmental conditions.Product Features: Stainless Steel Spiral Cage PulleySpiral cage structureThe unique spiral cage design can automatically clean the adhering materials during the rolling process, effectively preventing material accumulation and blockage. High-quality stainless steel materialMade of high-strength stainless steel, it features excellent corrosion resistance and wear resistance, and is suitable for humid, chemically corrosive or high-dust environments.Enhance the traction of the beltThe spiral structure increases the contact area between the conveyor belt and the rollers, effectively reducing slippage and improving transmission efficiency.Sturdy and durable designThe heavy-duty structural design and precise manufacturing process ensure long-term stable operation under high loads and harsh working conditions.Easy to maintainThe self-cleaning function reduces maintenance frequency and downtime, and extends the service life of the equipment.Widely appliedIt is applicable to industries such as mining, aggregates, cement plants and bulk material transportation, and is particularly suitable for materials prone to adhesion and complex environments.