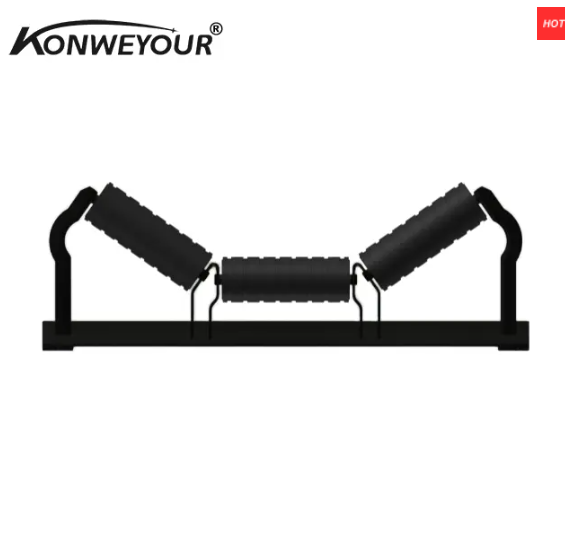

Product Features

Unique Pipe-Shaped Structure

The conveyor belt forms a fully enclosed tubular shape, effectively preventing material spillage and dust emission, ensuring a cleaner and safer working environment.

High Wear Resistance

Made from premium wear-resistant rubber compounds, the belt offers excellent abrasion resistance, extending its service life even in harsh conditions.

Strong Load Capacity

Reinforced with high-strength fabric or steel cord carcass, providing superior tensile strength and durability for heavy-duty and long-distance conveying.

Corrosion and Weather Resistant

The rubber covers protect the belt from corrosion, moisture, and various weather conditions, allowing stable operation in diverse environments.

Low Maintenance

Robust design minimizes wear and tear, reducing downtime and maintenance costs.

Versatile Applications

Ideal for mining, cement, chemical, and power industries requiring enclosed conveyor systems to transport bulk materials efficiently and safely.

Product advantages: Wear Resistant Pipe Rubber Conveyor Belt

Unique tubular structure to prevent material splashing

It adopts a tubular design to achieve fully enclosed material transportation, effectively preventing dust from flying and material from scattering, ensuring a clean environment and operational safety.

excellent wear resistance

High-quality wear-resistant rubber materials are selected to enhance the anti-wear capacity, extend the service life of the conveyor belt, and adapt to high-intensity working environments.

strong carrying capacity

High-strength canvas or steel wire rope frame, providing excellent tensile strength and stability, supports heavy-load and long-distance transportation.

Strong corrosion and weather resistance

The rubber covering layer effectively resists moisture, corrosion and harsh weather conditions, ensuring the smooth operation of the conveyor belt in various environments.

low maintenance cost

The robust design reduces wear and failure, lowers downtime and maintenance costs, and enhances production efficiency.

is widely used

It is widely applied in industries such as mining, cement plants, chemical plants, and power plants, meeting the high requirements for safety and environmental protection in closed conveying systems.